Ashley Tracy, director of Shapiro Metals Management System, still gets goosebumps thinking about the company’s 2019 Safety Stand-Down Day. “Everyone was relaxed; we saw smiles we’d never seen before,” she says. There were similar smiles on the faces of Battery Solutions’ quality, environmental, health, and safety (QEHS) team as they reflected on their 2020 Stand-Down Day. “Everyone was so excited for the event, and we don’t typically hear that in the QEHS world,” says Heather Soerries, QEHS analyst.

Shapiro Metals and Battery Solutions are among companies that observe ISRI’s Annual Safety Stand-Down Day, in which ISRI members shut down operations for at least one hour in every shift to participate in safety education. Taking charge of the education format, Shapiro Metals and Battery Solutions have devised creative ways to keep employees engaged during their safety training.

Hands-on Learning

Both companies found a hands-on approach to Stand-Down Day can be more effective than a PowerPoint. “Most of our employees are working in the warehouse; they’re not interested in sitting down for a presentation longer than five minutes,” Tracy explains. Tom Edwards, QEHS manager at Battery Solutions, views the day as an opportunity to make a big impact. “This is a break from staff’s normal day; it’s more than a PowerPoint,” he says.

In 2019, at Shapiro Metals’ most recent in-person Stand-Down Day, staff at the company’s 12 locations played I Spy Safety Issues, a game where they identified and discussed safety concerns throughout the warehouses. “We gave out notebooks and other items in goodie bags for staff to use and take home,” Tracy says. Shapiro Metals provided a continental breakfast and catered lunches to shift workers. “We wanted staff to feel like they were attending a business conference,” she adds.

In 2020, warehouse teams at Battery Solutions’ two locations tied safety and games into Stand-Down Day. “We did a scavenger hunt for fire extinguishers, eyewash stations, and more,” Soerries recalls. Warehouse employees also participated in an activity called Safety Survivor. “We divided the group into teams. Each team had clues, and went to different stations where they handled fire extinguishers, physically put a teammate through an eyewash station, or dealt with a station that went through a lead-acid battery spill,” Edwards says.

New Skills

For both companies, it was important for participating staff to familiarize themselves with safety equipment. “I’d never seen a fire extinguisher actually used,” Soerries says. “We went over all the steps of using a fire extinguisher, and we actually used the eyewash stations. It was important for everyone to be reminded where things were in the facility.”

Like Soerries, Tracy never had used a fire extinguisher before Stand-Down Day. “We have guidelines,” she says. “But if we had to act in an emergency situation, are we confident we know what to do?” Shapiro Metals brought in subject matter experts for its 2019 Stand-Down Day. “For our active-shooter training we had local law enforcement, and local fire departments led our fire extinguisher training,” Tracy says. After undergoing fire extinguisher training with local fire departments, Shapiro Metals employees were eager to share what they learned with their families.

Work and Home

When planning the 2019 Safety Day, Tracy and her colleagues Fred Stell-Smith and Diane Orange researched topics that promote safety at work and home. “If you can provide topics people are interested in and that affect them outside of work, you’ll get better participation and better feedback,” Tracy says. “Safety affects all parts of our lives, it’s not just about the workplace,” says Danielle Spalding, Battery Solutions’ director of marketing and communications. “It’s about taking things at work and teaching them to your family.”

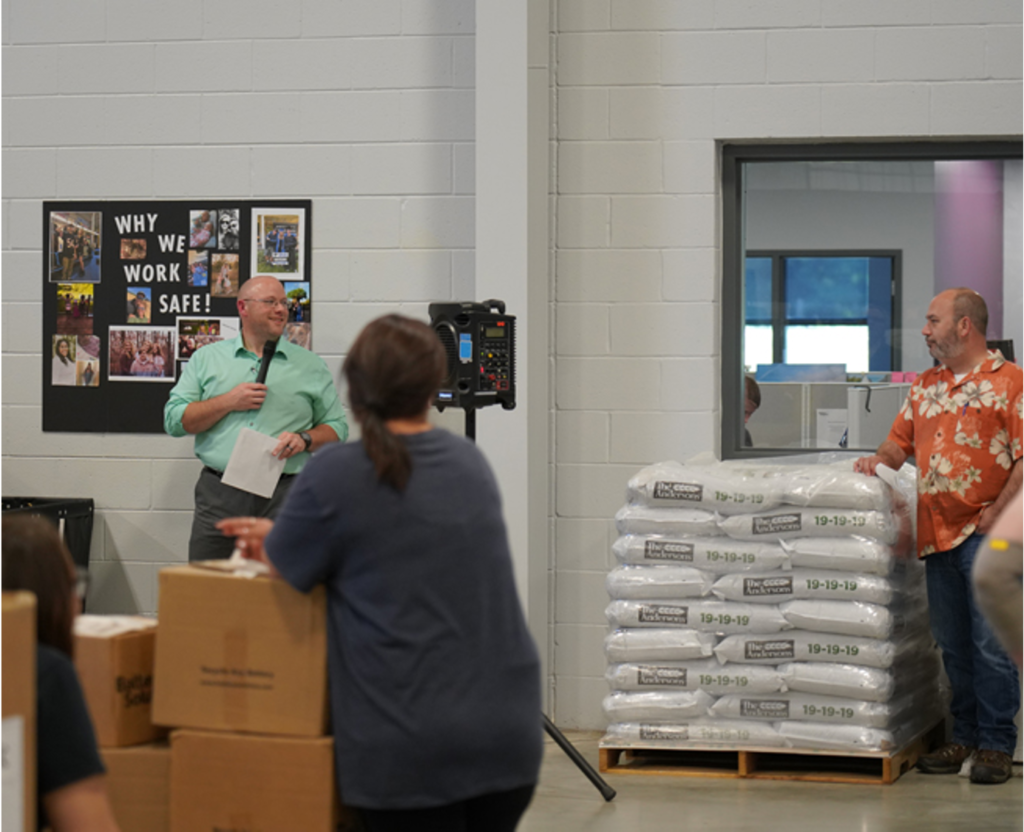

Battery Solutions elevated the “why” behind safety by asking warehouse employees to bring in pictures of loved ones for Stand-Down Day. The QEHS team hung the pictures on a bulletin board. “Above the photos we had the phrase ‘This is Why We Work Safe,’” Edwards says. It was a powerful message, and everyone was excited to see their families represented, Soerries adds.

For Battery Solutions employees, their 2020 Stand-Down Day was packed with safely-distanced engaging activities. “Everyone kept six feet apart and wore masks,” Edwards explains. An even bigger event is on the horizon this year. “We want to involve all staff at both facilities this year, and more community partners,” Edwards says. He’s been in touch with local fire departments to participate. “In an emergency situation, it can be scary to see first responders, but if you have the chance to meet them first, show them around the facility, and invite them to events like [Stand-Down Day], it helps ease people,” he says.

Have a SAFE Day

COVID-19 prevented Shapiro Metals from holding a 2020 Stand-Down Day, and is why the company adjusted the event in 2021. “This year, we’ve changed Stand-Down Day to SAFE: Safety Awareness For Everyone,” Tracy explains. These events are virtual, 90-minute trainings on similar topics to Stand-Down Day. “We still have some elements from the onsite trainings like lunches and making sure everyone takes time from work,” Tracy says. The company is holding SAFE events during each quarter and allows all staff the opportunity to stand down. “Fred Stell-Smith, who leads the event, makes sure everyone is present, including managers, and that everyone has their cameras turned on,” Tracy adds.

ISRI’s Stand-Down Day provides an important learning experience for employees that grows with repetition. “This event brings veterans together with newer employees; it’s an opportunity for team building and learning,” Spalding says. “We’re looking for an even wider range of engagement throughout our teams and community partners in 2021,” Edwards adds. Shapiro Metals seeks feedback from staff on SAFE so Tracy and her team can continue improving the event. “We call our feedback ‘The Good, the Bad, and the Ugly,’” she says. “[SAFE] isn’t done yet for this quarter; we’re still getting feedback and making adjustments as we go.”

Photos courtesy of Battery Solutions and Shapiro Metals, respectively.

Additional Resources