The REMADE Institute, a public-private partnership established by the United States Department of Energy (DOE), announced $43 million in new technology research on March 1. The institute selected 24 new projects as part of its latest round of funding.

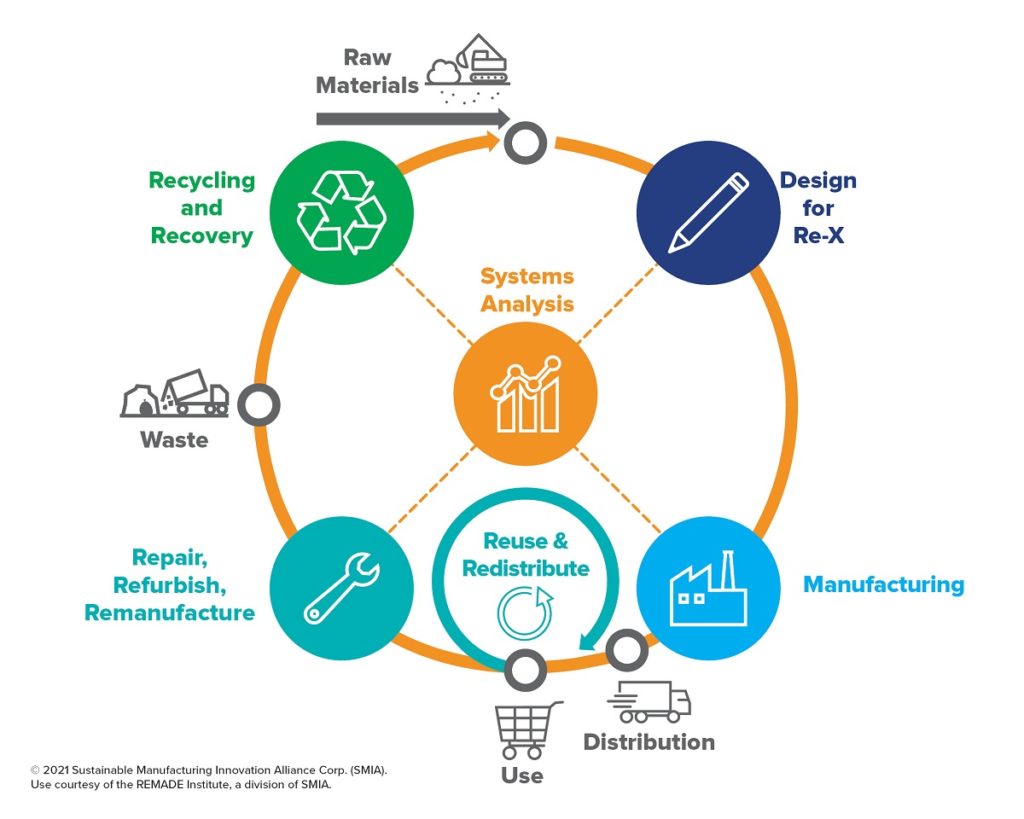

Founded in 2017, REMADE (Reducing EMbodied-Energy And Decreasing Emissions) is the first institute in the U.S. focused on accelerating the nation’s transition to a circular economy. Partnering with industries, academia, and national laboratories, REMADE enables early-stage applied research and development aimed at reducing embodied energy and consumption and decreasing emissions while increasing U.S. manufacturing jobs.

To that end, REMADE expects the new projects will help increase the recycling of materials in the U.S. by as much as 20 million metric tons per year, save up to 640 petajoules (PJ) of embodied energy per year, and decrease greenhouse gas emissions by as much as 30 million metric tons per year.

The institute selects proposals against the backdrop of its yearly national goals, says Dr. Nabil Nasr, REMADE’s founding chief executive officer. These goals provide a roadmap that helps identify high priority areas for funding. Proposals are chosen based on how much the projects are likely to forward the institute’s yearly goals. “The institute is looking to make a broader impact in the U.S.,” explains Nasr.

ISRI is a partner on one of the selected projects titled, “Material and Vehicle Design for High-Value Recycling of Aluminum and Steel Automotive Sheet,” along with the University of Michigan, Ford Motor Company, Novelis, Argonne National Laboratory (ANL), The Aluminum Association, and Light Metal Consultants.

The project aims to increase automotive sheet metal EOL post-consumer recycled content and reduce vehicle embodied energy and primary feedstock consumption. ISRI and its partners will produce a new analytical design for recycling tool for automotive metal sheet, and generate new knowledge on how vehicle design, recycling system infrastructure, and sheet manufacturing process decisions affect EOL sheet recycling.

Image above courtesy of REMADE

ISRI has been involved with REMADE since its inception, says Dr. David Wagger, ISRI’s chief scientist/director of environmental management. In 2013, ISRI, along with members from academia, the recycling industry, and national labs participated in early discussions about the need for a federally-funded research and development center focusing on sustainable materials.

ISRI worked closely with REMADE during those early meetings, says Nasr. “ISRI was engaged and involved in guidance, and became part of the team once we won the designation,” he notes. ISRI and the other participants discussed the main problem to tackle, “how do we get new recycling technologies on the market instead of letting them languish in a lab because they’re considered too risky,” Wagger recalls. Everyone around the table recognized the large gap between brainstorming ideas and putting them into practice and then into demonstration and commercialization. “The time from coming up with the technology to actually implementing it can be very long,” says Nasr. “Sometimes it never happens.”

Those meetings paved the way for the REMADE model—partners from the industry, trade associations, academia, and national labs create projects that drive down the costs of technologies essential to reuse, recycle, and remanufacture materials such as fibers, metals, polymers, and electronics. A technological solution that doesn’t involve input from those directly affected by the issue is less effective than a solution where all interested parties bring their experience, opinions, and expertise to the table. “If your solution isn’t taking in all the various factors, then you’ve got a solution no one can use,” says Nasr. In contrast, REMADE’s model, “helps gets technology to implementation in a much faster, focused, and economical way and drives the impact in a much faster way,” says Nasr.

Results from REMADE’s 2020 Impact Report highlight how well the consortium model works. Released on March 16, the report illustrates some of REMADE’s completed projects and how they’ve forwarded the institute’s national goals. For example, projected impacts from REMADE’s films and flexible plastics project include up to 50 petajoules of embodied energy savings, up to 2 million metric tons in material savings, and reduce up to 2 million metric tons in greenhouse gas emissions.

On the heels of REMADE’s announcement of the 24 new projects, Nasr is excited to announce the institute will announce a new RFP to be released in April. The total amount is still in process and the amount tends to fluctuate right until the final RFP is released. As of Friday, March 26, the total was $46 million. “There’s a lot of opportunities for organizations that are interested in the future to apply for new projects,” he says.